Machine Inspection Services

Keeping your machine tools in good working order starts and ends with proper alignment. The value of this small investment cannot be overstated. Machine tools lacking proper alignment and pitch error compensation are not fully productive. Over time, these errors become magnified in faulty machine operation and substandard parts.

Who can afford that?

The CNC-DOC recommends a baseline reading of alignment for all service work and regular checks and adjustment as part of any ongoing preventive maintenance program.

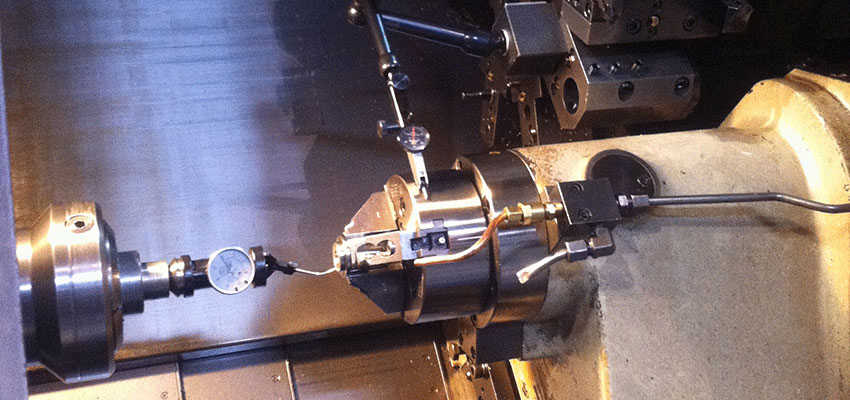

We offer the following services and equipment for your alignment needs:

- Machine Inspection

- Machine Leveling

- Machine Calibration

- Troubleshooting Problem Areas

- Laser Alignment

- Laser Compensation

Calibration

Servicing large metal cutting machines is very costly, and the price for non-compliance can be devastating. Many of today’s manufacturers have opted to implement a disciplined approach to qualifying and certifying their equipment in order to satisfy internal as well as external traceability requirements such as ISO, QS and ASME B5.54 certification and compliance. Equally important is the monitoring of machine compliance characteristics over a specific measure of time.

CNC-DOCs calibration services optimize machine performance by providing calibration designed to ensure accuracy and repeatability when producing parts. Our team will assist you with tracking your machine’s performance and preparing for planned maintenance instead of reacting to sudden non-compliance. In a few words, calibrating your machines with our precision measuring equipment will give you and your customers comfort knowing that the product you produce and the product they receive was manufactured on equipment capable of meeting close tolerance results.